+91 75987 34364

Polyisocyanurate(PIR) Ducting

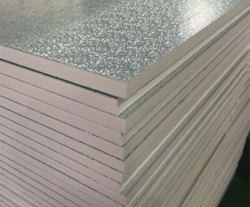

SMART Panels are crafted from completely CFC and HCFC-free closed-cell Polyisocyanurate (PIR) foam, encased between Aluminium foil or Kraft Paper. They come in standard dimensions of 4m (L) x 1.2m (W) with thickness options ranging from 12mm to 75mm (custom lengths available).

SMART Panels are versatile and widely used in the construction of HVAC Ducting Systems, Underdeck and Overdeck Insulation, Wall and Roof Insulation, Cold Storage Facilities, Glass Facades, Floor Insulation, Cavity Insulation, False Ceilings, and more.

These panels are cost-effective and energy-efficient, offering up to 20% energy savings. They feature ultra-low thermal conductivity (0.021 W/m.K), are eco-friendly (recognized as a Green Building Product), fire-retardant (certified as Class 0 under BS 476 by Exova Warringtonfire – US & UK, CBRI Roorkee – India, and TUV SUD – Singapore), rodent-resistant, have minimal water absorption, and are impervious to water vapor. Additionally, they provide acoustic insulation and facilitate quick fabrication and installation.

SMART Panels serve as superior replacements for:

- GI Ducts insulated with Nitrile, XLPE, or Glasswool in HVAC systems.

- Thermocol, Glasswool, Nitrile, or Phenolic foam for Underdeck and Overdeck Insulation.

- Calcium Silicate tiles for False Ceilings.

- Nitrile or XLPE for Floor Insulation.

12mm – 75mm thickness both side aluminium foil

With PIR smart Pre-Insulated Panels, exceptional insulation quality is achieved due to the combination of Aluminium foil and advanced PIR foam. This blend ensures superior internal air quality, a polished external finish, and a durable, lightweight material. These panels are easy to transport, fabricate, and install.

SMART Panels – Applications

SMART Panels are globally utilized in Commercial, Residential, Hospital, and Industrial settings for HVAC Ducting Systems, Underdeck and Overdeck Insulation, Wall and Roof Insulation, Cold Storage, Glass Facades, False Ceilings, and more. In industries demanding stringent quality and hygiene standards such as food processing, pharmaceuticals, laboratories, electronics, and healthcare facilities smart Panels deliver outstanding insulation solutions to meet these requirements. At present we are doing projects on spinning, weaving, OE (open end) mills in textile industrials. Also we had done almost 80 projects in this. Meanwhile we are doing more projects in this. As well as we provide the test certificate along the material.

General characteristics :

SMART Panels are crafted using entirely CFC and HCFC-free closed-cell Polyisocyanurate (PIR) foam, enclosed between layers of Aluminium foil on both sides.

DIMENSIONAL & TECHNICAL CHARACTERSTICS

| Dimensions of Panel (Lx W) | 4000 mm x 1200 mm |

| Aluminium foil type | Embossed / Embossed, Embossed / Plain / FSK |

| Aluminium foil thickness | FSK-FSK, 80-FSK, 80-80, 80-200, 200-200 Microns FSK-45, 45-45, 45-80 |

| Panel thickness | 12/15/20/25/30 mm (Indoor Application) 20/25/30 mm (Outdoor Application) |

| FIRE PROPERTIES : | |

| Fire Propagation | Class 0, according to BS 476 Part 6 & Part 7 |

| Surface Spread of Flame | Class 1, according to BS 476 Part 7 |

| Smoke Development Index | Class A, according to ASTM E-84 |

| INSULATION PROPERTIES : | |

| Material for Insulation | PIR (Polyisocyanurate) |

| Thermal Conductivity | 0.021 W/m.K |

| Density | 45 +3 Kgf/m² |

| OTHER PROPERTIES : | |

| Water Vapour Transmission | 0.00 perms |

| Water Absorption | 0.03 % |

| SPECIFICATION OF USE : | |

| Air Pressure | Upto 2000 Pa |

| Air Velocity | Upto 35 m/sec |

| Friction Coefficient | 0.0135 |